| External diameter : | Ø6mm-100mm |

| length: | 100mm-6000mm |

| material: | 45#DINCK45/JIS45Cand35#DINCK35/JIS35C |

| Chromium plating thickness: | 10~25μm |

| Chromium plating hardness: | 850HVMin |

| Surface roughness: | Ra0.4~0.8um |

| Straightness: | 0.2/1000mm |

| yield strength: | According to the material and customer requirements |

| Elastic strength: | According to the material and customer requirements |

| Elongation: | According to the material |

| Bending test: | According to customer requirements |

| surface treatment: | 1.Chrome plating |

| 2.Hardening by quenching | |

| 3.Dehydrogenation & tempering |

In a piston engine, a piston rod joins a piston to the crosshead and thus to the connecting rod that drives the crankshaft or (for steam locomotives) the driving wheels.

Gerdau has a wide range of steel products which are marketed throughout India. In several states in which it operates, produces long carbon steel and specialty steel, and offers related services.

Its products are used in various sectors such as construction, infrastructure, industry, agriculture, mining, petrochemical, railway, defence, orthodontic, medical and steel.

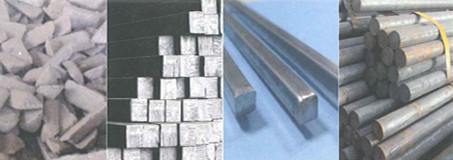

• Pig Iron

• Billets

• Squares

• Round Bar

• Hexagons

• RCS

• Flat Bars

• Grades

• Standards

• Cold Finished Bars

• Heat Treated Bars

ROUND BARS :

16,17,18,19, 20, 20.4,20.64 MM

22,23,23.5, 24, 25, 26,27 MM

27.5,28, 28.5 ,30,30.5,31,31.5, 32,33,34 MM

36, 37, 38,39.3, 40, 42, 43,44,45 MM

46.5,48, 50,52, 53,54, 56,57 MM

58,60,62, 63, 65 ,66,68 ,70 ,72,75,80 ,85 MM

TOLERANCES ON SIZE, LENGTH AND STRAIGHTNESS IS 3739 GR 1

HEXAGONS

18.5 TO 40.5 MM

RCS ( SQUARES)

63 , 65 , 68 ,75 MM

FLAT BARS

70 TO 101.6 MM WIDTH WITH 6MM TO 26 MM THICKNESS

TOLERANCES ON SIZE, LENGTH AND STRAIGHTNESS IS 3739 GR 1

GRADES (SEPARATE TABS)

ALL GRADES OF CARBON STEEL,

CHROME MANGANESE STEEL,

FREECUTTING STEEL,

SILICO MANGANESE STEEL,

CHROME MOLY STEEL,

CHROME MOLY NICKEL STEELS,

BALL BEARING STEELS,

COLD EXTRUSION GRADES,

MICRO ALLOYED STEELS.

STANDARDS (SEPARATE TABS)

STEELS MADE AS PER INTERNATIONAL STANDARDS LIKE BIS / BS / EN / SAE / ASTM / AISI / DIN / JIS / GMT

COLD FINISHED BARS

DRAWN / PEELED / GROUND ROUNDS & HEXAGONAL